To accomplish this the wastewater is first heated to approximately 85C in a vacuum during the evaporation process. NVD uses the barometric height of water column approximately 103 m to generate a natural vacuum in the headspace above the water column.

Natural Vacuum Distillation Energy Conservation Dr Darrin Lew

Natural Vacuum Distillation Energy Conservation Dr Darrin Lew

You can also choose from high productivity easy to operate and energy saving water vacuum distillation as well as from vacuum distillation rotary and drum evaporator water vacuum distillation and whether water vacuum distillation is manufacturing plant farms or food beverage factory.

Vacuum distillation of water. The goal is to separate the impurities from the clean water. A wide variety of water vacuum distillation options are available to you such as electric fuel oil. This low-pressure environment makes it possible to carry out the desalination process at low temperatures which can be easily attained from renewable energy sources or from waste heat sources.

This enables small lot manufacturing with better functionality for several different types of production with a single system. The so-called vacuum distillation is one of the distillation methods. Vacuum desalination is a process by which water is vaporized at a lower temperature when subjected to vacuum pressure.

Vacuum distillation variation with a simple distillation. Then open the apparatus to the atmosphere by opening the pinch clamp on the trap or removing the tubing on the vacuum adapter. Cool open to atmosphere then turn off vacuum.

Low Scaling and corrosion potential. Cracking is minimized by injecting steam into the oil at the furnace inlet to give high velocities and short residence times in the furnace tubes. The CEH-400B centrifugal vacuum distillation system was developed to be a small-scale plant unit capable of processing numerous products at lower production rates in a manufacturing environment.

Laboratory water distillation equipment for distilled water product attribute Model FPR Rotary flaskL 1050 Receiver L 5L10L10L Motor Power W 120180 Vacuum rate Mpa 0098 Rotation speed rpm 5-110 Evaporating speed H2OLh 358 Power V 220 Dimension Cm 55X35X110120X80X220 product show Supporting equipment Product advantage PackingShipment Contact Lynn Zhang. But under vacuum typically around 27 Hg this boiling point can drop to 135F 57C or lower. Distillation is the process by which substances are separated by manipulating the temperature andor pressure of a mixture.

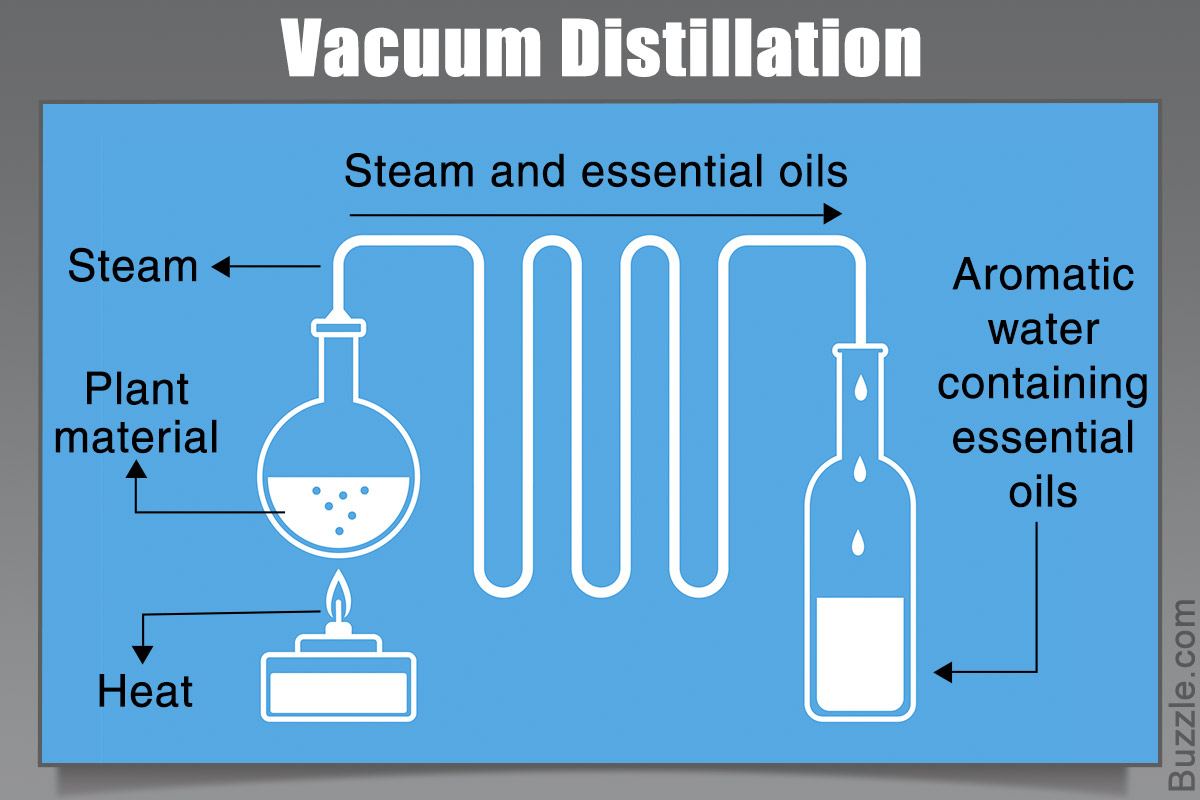

The simulation results showed that a vacuum is formed in the ejector throat where the speed also reached its. Vacuum distillation is simply distillation at pressures below one atmosphere. A vacuum distillation is performed by applying a vacuum source to the vacuum adapter of either a simple or fractional distillation Figure 548.

The apparatus consists of an oven in which the compound to be distilled is placed a receiving portion which is outside of the oven and a means of rotating. The heat energy requirement for desalination using a distillation process can be brought down by reducing the boiling temperature. 7- 9 kPa 10 13 PSIA Lowest Boiling Temperatures.

For instance it is to reduce 95 of disposal cos. It is usually used to separate substances that are easy to decompose when heated to boiling point at atmospheric pressure or to combine with other distillation methods such as steam distillation to reduce distillation temperature and improve separation efficiency. Typically the vacuum is generated by a water aspirator or a membrane pump.

For instance at atmospheric pressure water boils at 212F 100C. The vacuum distillation and desalination system of claim 4 wherein the vacuum generation unit further includes a steam boiler a water supply a condensation-induced dual-action piston-cylinder vacuum generation module a vacuum pump actuated with the vacuum generation module wherein steam hot water and return water flows through the vacuum distillation and desalination system. The ocean water is placed under a vacuum to lower its boiling point and has a heat source applied allowing the fresh water to boil off and be condensed.

Here it is heated in a furnace to over 425 C 800 F and charged into the flash zone of the vacuum tower. 30 40 C 86 104F Low Electrical Energy Consumption. When the pressure is lowered inside the apparatus solutions boil at a lower temperature.

The boiling temperature of seawater can be lowered to as low as 400C by the creation of a vacuum. A new machine to produce distilled water was provided which includes a heat pump system and a vacuum system. The use of the vacuum evaporation technique has shown several advantages among different industrial fields.

And in the vacuum system of this new machine the ejector is the key component. The thermal separation process serves this function during vacuum distillation. Vacuum distillation is often used in large industrial plants as an efficient way to remove salt from ocean water in order to produce fresh water.

This has two distinct advantages. Three kinds of ejectors were studied by using FLUENT software to simulate their parameters. Lastly turn off the vacuum.

The bottoms stream from the atmospheric distillation column is sent to the vacuum distillation unit. To stop the distillation remove the heat and cool the flask in a tap water bath. This is known as desalination.

150 kWhton of distillate 057 kWhgal of distillate Ozone Friendly refrigeration gas R 134 Designed for low to medium flow wastewater streams. Reduced pressure permits vaporization at reduced temperatures. In a kugelrohr a short path distillation apparatus is typically used generally in combination with a high vacuum to distill high boiling 300 C compounds.

Vacuum distillation is the oldest form of desalination. In rotary evaporation a vacuum distillation apparatus is used to remove bulk solvents from a sample.